How to find the right Thermal Interface Materials(TIMs) from Sinoguide Technology?

Firstly, you need to know your application for choosing the right TIM

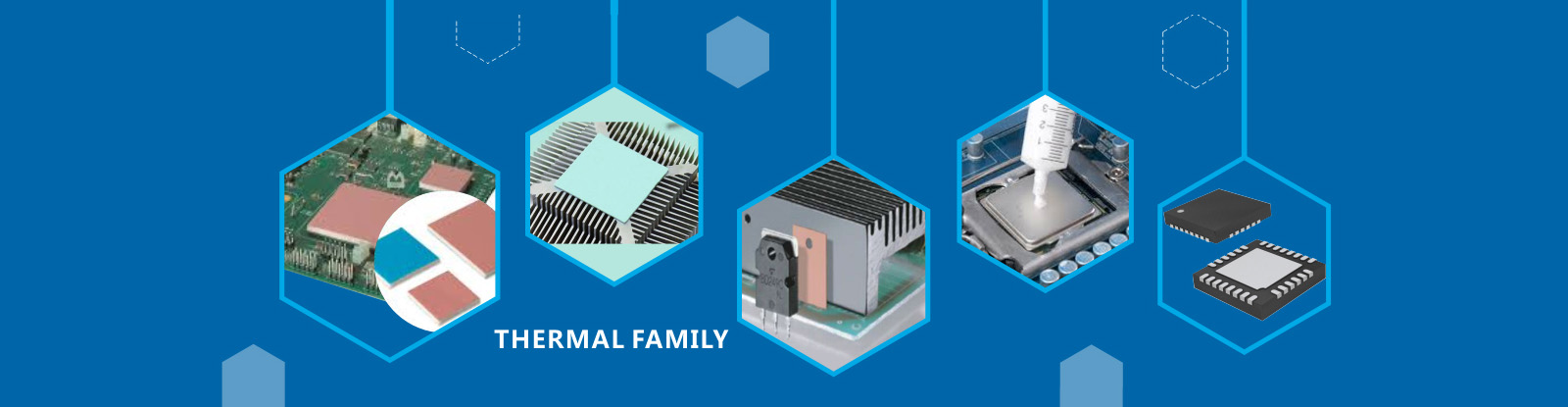

As component powers continue to grow, so do their cooling requirements. It is in common sense that for every 10°C rise of the junction temperature the failure rate doubles. Thus, there is an urgent need to remove heat from hot chips to the surrounding air stream. Demand has led to a variety of new thermal management systems. But nearly all of these continue to use thermal interface materials, or TIMS, to effectively provide heat flow across the mating interfaces of cooling systems.

The essential purpose of TIMs is to maintain effective transfer of heat from hot chips to dissipating devices such as heat sinks or spreaders. As heat flows, it encounters thermal resistances that impede overall heat transfer. TIMs reduce the most problematic of these, the contact resistance between the mating parts (heat source – heat sink). Air gaps significantly limit heat flow from the hot component into the sink or spreader. An effective TIM replaces the gaps created by the non-smooth mating surfaces with a material whose thermal conductivity is much greater than that of air. Basically, it replaces poor conduction from point contacts and air to enhanced conduction through solids.

Most TIMs developed by the Sinoguide Technology is silicone based without any oil bleeding through special handling. Some level of pressure is usually needed between the mating surfaces to well compress the thermal pad to reduce contact resistance.

Application Issues for Thermal Interface Materials

While thermal interfaces and TIMs are often considered well into the design process, several factors should be considered when it’s time to choose a thermal interface material:

· Thermal impedance is the single most important specification measured in degrees Kin2/W. Thermal impedance is an application-specific measure of the ratio of the temperature difference between two mating surfaces to the steady state heat flow through them. Thermal impedance usually decreases with added mounting pressure and contact area, but increases with the thickness of the TIM.

· Thermal conductivity, in W/mK, measures a material’s ability to conduct heat regardless of its thickness. A bulk measurement, thermal conductivity values can be used for comparing TIMs, but it does not describe a TIM’s ability to minimize contact resistance in an application.

· The gap space between the heat source and the heat spreader. As a rule, the thinner the TIM the better, but because mating surfaces are never perfectly flat, a minimum material thickness may be needed to accommodate non-flatness issues.

· Surface flatness of mating surfaces is important for determining the type of material.

· Electrical isolation, measured in kV, is sometimes needed to be considered.

· Compressibility is important when working with irregular surface as when covering a number of components.

· Temperature range in the interface determines which materials can be used.

· UL flame class rating. A UL flammability rating requirement is needed for many TIM applications. All thermal conductive materials developed by Sinoguide Technology is UL verified.

SinoGuide Engineers work closely with customers to provide a seamless design cycle from concept to prototype to production utilizing our broad range of technologies and capabilities to ensure innovative, fully optimized thermal solutions and systems.

Sinoguide Technogy is a renowned supplier of thermal interface materials for the electronic, medical, semiconductor, optics, automotive and aerospace industries. For more information, call Sinoguide Technology at +86-755-89375091 or email Sales@sg-thermal.com.

LATEST NEWS

SinoGuide

- Technical buyers and product designers can choose ... 2018-12-21

- SinoGuide Thermal Management to Suit Your Every Pu ... 2017-12-27

- Efficiently Transfer Heat Thermal interface materi ... 2017-12-20

- SinoGuide Technology Announces Silicone Thermal Pr ... 2017-12-01

- The Thermal Conductivity's Influences of Thermal I ... 2017-11-29

- Thermal Gap Tape Helps to Improve The Life of a LE ... 2017-11-17

+86-755-89375091

Contact:Sales Manager

Mobile:+8618664916620

Email:sales@sg-thermal.com

Add:Zhonghe Street, Pinghu Town, Longgang District, Shenzhen City, China

sinoguide

sinoguide sinoguide

sinoguide sinoguide

sinoguide